Welcome to BMW-Brilliance

BMW in China is dedicated to expanding our fully-electric fleet to provide customers with more choices on their journey towards a more sustainable future.

BMW’s Efficient Dynamics Strategy reduces fuel consumption and emissions while enhancing dynamic performance to deliver Sheer Driving Pleasure.

With lightweight design, we further optimise fuel efficiency, extend electric range, and elevate driving experiences.

Collaborate closely with our dealer network to extend the sustainability experiences into the final consumer touchpoint, through initiatives including BMW Network Transformation (NT) Green Star Project, dealer empowerment, and Environment, Health, and Safety (EHS) activities.

Collaborate with State Grid Smart IoV to provide renewable electricity for NEVs charging, advance charging technology research and innovation, and promote exceptional charging service.

All charging infrastructure deployed under BMW Brilliance's joint venture, Beijing IONCHI New Energy Technology Ltd., operates on 100% renewable electricity.

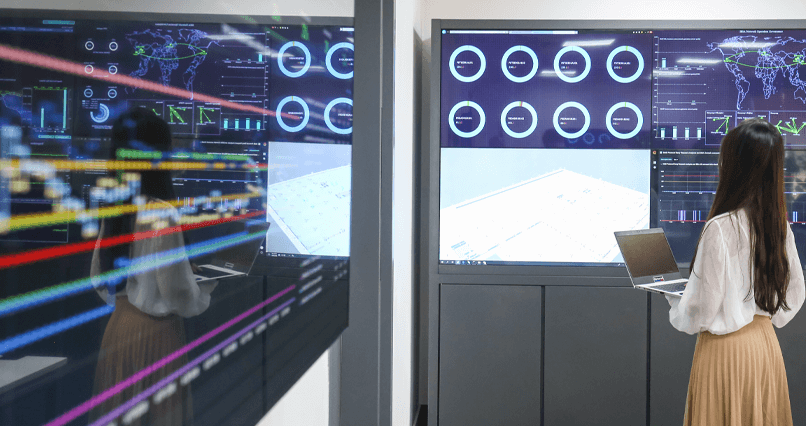

Utilize innovative technologies to facilitate flexible and efficient production, minimising the use of resources and using digital solutions in the fields of data science, AI, virtual planning and development.

Our approach targets simultaneous achievement of operational excellence and reduced CO₂e emissions.

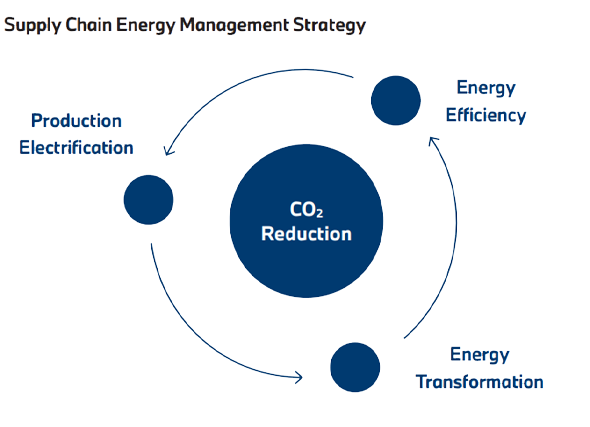

Actively leverage digital platforms with AI-driven technology to collect and analyse energy consumption data, continuously improving energy efficiency to drive more intelligent, sustainable energy management across operations.

Lead the energy transition in production and operations by significantly replacing fossil fuels with renewables to transform our energy portfolio.

100% renewable electricity used for all manufacturing sites in Shenyang and 36 non-manufacturing sites across the nation.

Continue to increase on-site solar PV installation for the Shenyang base and the Beijing non-manufacturing operative site.

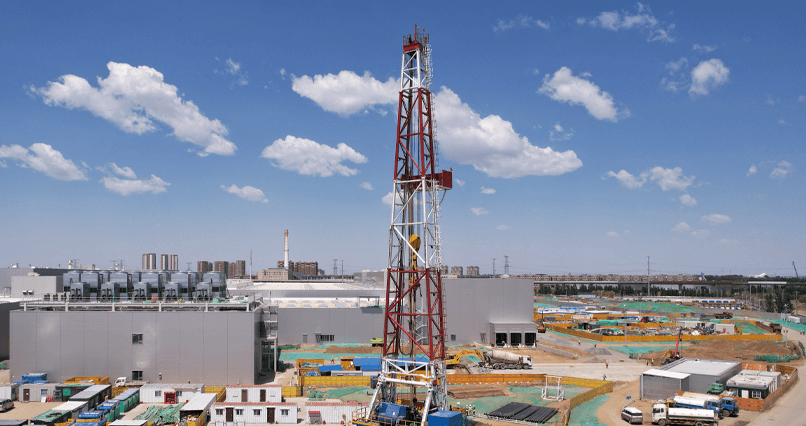

Innovatively apply medium-deep geothermal technology to provide 100% fossil-free heating for our powertrain plant and HVB Centre.

Expand the adoption of low-carbon and multimodal transportation, such as clean energy vehicles, rail and sea freight.

Implement hydrogen-powered trucks for transporting components and finished vehicles.

Expand the use of pure electric trucks in after-sales logistics operations.

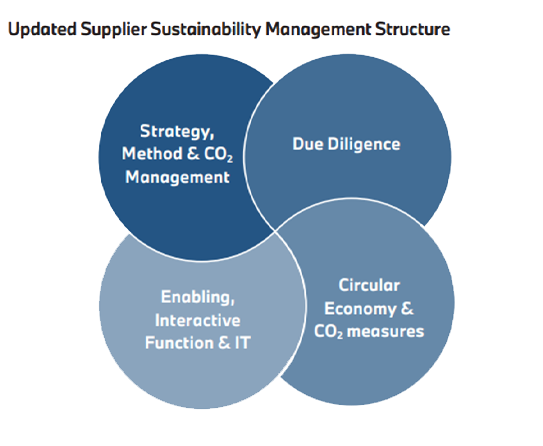

Integrate environmental criteria into supplier selection and management process, which weights the utilisation of renewable electricity and secondary materials as key selection criteria.

100% renewable electricity adopted for self-production by all High Voltage Battery (HVB) cells suppliers.

100% aluminium ingot foundry shop suppliers adopted renewable electricity.

Cooperate with suppliers to sign joint Memorandums of Understanding (MoU) for low-carbon aluminium.

Support suppliers through training, digital tools, and collaborative platforms, equipping partners with the knowledge and digital tools needed to navigate the transition to sustainability.

Use the Carbon Disclosure Project (CDP) Supply Chain program to assess the decarbonization performance of our supply chain.

Our efforts and practices have earned the recognition as a "Five-Star Green Supply Chain Enterprise" by the Ministry of Industry and Information Technology (MIIT).

Promote circularity across the entire product lifecycle, guided by the principles of the circular economy.

Explore the development of bio-based materials using tea leaves, as well as the application of surface spray-free materials in interior parts, lightweight materials, and surface laser engraving technology.

Strengthen our collaboration with suppliers to optimise transaction flow through standardised processes and enhanced coordination with the central departments to accelerate remanufacturing development cycles, further increasing the efficiency of material recycling and vehicle parts turnover.

Expand ongoing research and design investments for remanufactured parts to include starters, alternators, and electrical drive units.

Advance circular economy principles through efficient resource use, waste minimisation, and sustainable production/consumption patterns.

Continue to increase the use of secondary materials in our vehicles by working closely with our supplier partners.

Implement aluminum ingot scrap closed-loop recycling and increased secondary aluminum ingot usage for BMW Brilliance foundry shop production.

Expand secondary aluminum application to all rim projects at pilot suppliers, achieving 75% recycled content through validated collaborations.

Apply recycled thermoplastics to interior and exterior components (floor panels, consoles, seats, etc.).

Continue closed-loop recycling for nickel, cobalt, and lithium from retired batteries, including secondary nickel integration in high-voltage batteries.

Advance precious metal recycling, achieving over 70% secondary raw material use of palladium and rhodium.

Implement closed-loop water systems, expanded the use of reclaimed water in production processes and daily operations, and ensured a stable supply of reclaimed water for the production process and cooling towers.

Recycle ceramic and iron mud from engine factories as raw materials for cement production.

Recycle paint shop discarded solvents through distillation for reuse and further reduce Volatile Organic Compounds (VOCs) emissions.

Recycle scrap steel and scrap aluminium through collaboration with our manufacturing partners.

Rethink:

Introduce new plastic universal containers based on the modularisation concept with replaceable parts to enhance the reuse of existing resources.

Reduce:

Utilise lean materials to replace steel based on the mindset of light-weight design to increase efficiency during logistics and transportation.

Reuse:

Strengthen the circular use of steel containers by implementing standardized reuse processes.

Introduce flexible-structure containers to meet diverse demands.

Apply returnable packaging materials in the aftersales parts logistics of Shenyang Regional Distribution Centre.

Recycle:

Conduct feasibility studies and pilot implementation of recycling and reuse of non-steel materials, e.g. apply secondary material in plastic containers and actively explore the organic combination of biomaterials and plastics.

Incorporate circularity concepts into the architectural design of exemplary dealerships to minimise the ecological footprint and promote resource recycling and reuse.

Set up HVB recycle rooms at dealerships for customer convenience.

HVB recycling: 100% retired HVBs recycled.

HVB reuse: Scale up and diversify secondary use of HVBs, e.g. forklifts, pallet trucks, power storage stations, etc.

Accelerate the expansion of our parts remanufacturing capabilities and scope, significantly reducing carbon emissions and wastewater, as well as the use of raw materials in the production process.

Deliver high-quality remanufactured parts by applying advanced remanufacturing technologies and stringent quality standards.

Implement proactive measures to achieve precise management of parts remanufacturing and recycling, driving efficiency and sustainability across operations.

Government:

Support sustainable development related activities, such as the “National Low Carbon Day”.

Non-governmental Organisations (NGOs):

Participate in the UN Global Compact Global Development Initiative (GDI) for Sustainable Development Goals (SDG) Series Report: A white paper on the carbon footprint of electric vehicle batteries and low-carbon circular development.

Industry Association:

Host a series of technical expert conferences and workshops to promote technical exchange with leading business partners.

Think Tanks:

China Development Research Foundation Supported Research Project: Promote green transformation of the industrial chain through thematic workshops, field research and expert interviews.

International Sustainable Mobility Research Platform: Collaborate with Tsinghua University and international academic scholars, address critical topics of relevance to BMW’s sustainability goals.

Promote renewable electricity implementation throughout our supply chain.

Signed joint Memorandums of Understanding (MoU) for electrolytic aluminium and for recycled aluminium.

Encourage our supplier partners to fulfill requirements — from ESG risk management to responsible sourcing practices — throughout the entire value chain, thereby establishing a supplier network that shares common values in environmental and social standards.

Our supplier chain empowerment initiatives focus on creating platforms for knowledge sharing, innovation and collaborative problem-solving.

Facilitate meaningful dialogue and partnership opportunities that drive sustainable practices across our supplier network through events like the BMW China Sustainability Supplier Day and BMW Brilliance Supplier Tech Day.

Reshape comprehensive capabilities of front-line employees.

Enable talent development to accelerate NEV transformation and digitalisation.

Empower partners to open up new sales models and implement a retail transformation strategy.

Continue to be stringent in dealer management of Environment, Health, and Safety (EHS) to deliver exceptional customer experiences.

Drive sustainable dealer transformation through the BMW NT Green Star Project, adapting to market evolution while creating tangible community and stakeholder value via eco-conscious operations.

Continuously refine and innovate our recruitment process to embrace more talents by adopting a candidate-centric recruiting strategy.

Continuously provide comprehensive, future-focused training programmes for all levels and positions, nurturing personal growth and development of our employees.

Continuously push boundaries in models, technologies, resources, and engagement to revolutionise the employee learning experience.

Aspire to cultivate a collaborative workspace that embraces all and cherishes each employee, whose wisdom and enthusiasm constitute the cornerstone of our company.

Our varied perspectives will stand us in good stead for future challenges.

Enhance employee engagement by creating diverse communication channels, conducting employee surveys, and strengthening the connection through product and brand experience.